Coax Compression Connector Installation: Difference between revisions

Created page with "This is the F Type Compression connector being used by the satellite and cable television industry. The F Type compression connector should NOT be confused with earlier "scre..." |

No edit summary |

||

| Line 1: | Line 1: | ||

This is the F Type Compression connector being used by the satellite and cable television industry. The F Type compression connector should NOT be confused with earlier "screw on" or push on connectors that don't stay put. RG-6 Compression F-Connectors are secured into place by use of a special tool. They are designed for use with satellite and cable applications. | This is the F Type Compression connector being used by the satellite and cable television industry. The F Type compression connector should NOT be confused with earlier "screw on" or push on connectors that don't stay put. RG-6 Compression F-Connectors are secured into place by use of a special tool. They are designed for use with satellite and cable applications. | ||

[[File:ftypecompression02.png]] | |||

1 Strip back 3/4" down to the center wire. Be sure not to crush down insulator foam layer. | 1 Strip back 3/4" down to the center wire. Be sure not to crush down insulator foam layer. | ||

Revision as of 21:55, 16 July 2015

This is the F Type Compression connector being used by the satellite and cable television industry. The F Type compression connector should NOT be confused with earlier "screw on" or push on connectors that don't stay put. RG-6 Compression F-Connectors are secured into place by use of a special tool. They are designed for use with satellite and cable applications.

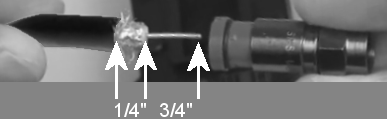

1 Strip back 3/4" down to the center wire. Be sure not to crush down insulator foam layer.

2 Carefully remove outer insulating sleeve another 1/4" back exposing braided shield. Do not damage braided shield wire.

3 bend back the braided shield strands against outer sleeve at a 90 degree angle from the cable.

4 leave the tin part of the sleeve which is under the braiding intact against the foam insulation.

5 Slide compression fitting on over cable until foam insulation is visible on the front inner diameter but not extending past

6 Attach compression tool to compress fitting onto cable. Do not use excessive force. Compress only until black band is fully reduced..

7 Cut and remove excess inner core extending beyond front, leaving only a small amount extending.