Speaker Repair: Refoam: Difference between revisions

mNo edit summary |

mNo edit summary |

||

| (5 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

This guide is applied to the speaker woofer. | This guide is applied to the speaker woofer. | ||

[[File:woofer.jpg]] | |||

The foam flex ring surround may deteriorate with age and may be replaced without the need to replace the entire woofer. This requires a little cutting, scraping, cleaning, and careful application of a new foam surround using adhesive. | |||

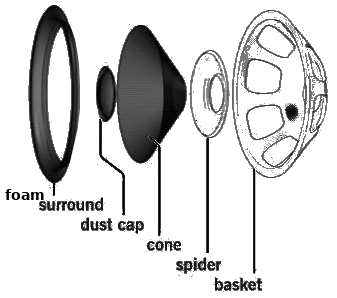

[[File:wooferpartsrefoam.png]] | |||

1. Remove speaker woofers from the cabinet. | 1. Remove speaker woofers from the cabinet. | ||

| Line 15: | Line 21: | ||

:b) for angle lip cone: Apply an 1/8" bead of glue to the underside inner lip of the foam ring. | :b) for angle lip cone: Apply an 1/8" bead of glue to the underside inner lip of the foam ring. | ||

6. Apply the adhesive evenly and waste no time in attaching to the speaker cone. Make sure | 6. Apply the adhesive evenly and waste no time in attaching to the speaker cone. Do not use too much glue, the glue is formulated for this purpose and should be very effective at the correct conservative amount. Make sure the foam is aligned on the cone. Work the new edge to cone for several minutes by pressing lightly with your fingers. Careful not to slide the ring out of position. keep working your way around the ring and repeat in the same direction. Do this for 2 - 5 minutes, or until you notice the ring remains snug in that it is not pulling up with the glue, you may have to do this longer for the angle lip type of speaker. You have have to utilize a custom pressure ring, see notes below on custom pressure ring. Once firm, allow the glue to drive for at least one full hour. | ||

7. Once dry time is observed, prepare the speaker cone for the gluing of the outer foam ring. You will press lightly and flex the cone while you observe the movement of the foam ring. You don't want to glue the outer part of the foam ring in such a way that it restricts movement of the cone or you will negatively impact the performance and sound of the woofer. This step is known as exercising the cone and will allow you a sense of the range of movement of the outer ring. The foam ring will | 7. Once dry time is observed, prepare the speaker cone for the gluing of the outer foam ring. You will press lightly and flex the cone while you observe the movement of the foam ring. You don't want to glue the outer part of the foam ring in such a way that it restricts movement of the cone or you will negatively impact the performance and sound of the woofer. This step is known as exercising the cone and will allow you a sense of the range of movement of the outer ring. The foam ring will need to be centered based on movement of the cone rather than visually by its position on metal frame. Observe the position the foam ring resides on the frame when the cone moves without scraping on the voice coil. We want the foam ring to reside at this place when glued so that the foam ring serves to allow equal and full range of movement when the speaker is operational. The ideal spot will ensure there is no contact scraping of the voice coil during movement. You may notice that the foam ring does not visually appear perfectly centered within the metal frame, however, what is more important is that it is residing where cone movement is centered and correct. | ||

8. Slip the tip of the glue bottle between the foam ring and the speaker frame edge to apply glue between the foam ring and speaker frame. Apply the glue between the foam and frame all the way around the circumference of the speaker before pressing. Exercise the cone once again and carefully observe movement to make sure it is even, centered, and that the foam ring is at the ideal spot. Once you have confirmed the foam ring is centered start applying pressure with your fingers working your way around the edge. Press down evenly while working your way around the outer ring. Note that you will probably see some wrinkling of the new edge, and this is typical to a slight degree as it will subside as the glue dries. Give the glue an hour to dry. | 8. Slip the tip of the glue bottle between the foam ring and the speaker frame edge to apply glue between the foam ring and speaker frame. Apply the glue between the foam and frame all the way around the circumference of the speaker before pressing. Exercise the cone once again and carefully observe movement to make sure it is even, centered, and that the foam ring is at the ideal spot. Once you have confirmed the foam ring is centered start applying pressure with your fingers working your way around the edge. Press down evenly while working your way around the outer ring. Note that you will probably see some wrinkling of the new edge, and this is typical to a slight degree as it will subside as the glue dries. Give the glue an hour to dry. | ||

| Line 25: | Line 31: | ||

10. Reinstall the woofer in the speaker enclosure and reconnect the wires observing proper polarity. | 10. Reinstall the woofer in the speaker enclosure and reconnect the wires observing proper polarity. | ||

done! | |||

* custom pressure ring - this is a method to apply constant pressure to the inner foam ring glued to the cone while the glue dries. | |||

* shimming the cone - this is not covered in this guide. It is a technique which requires removal of the dust cap so that the shim is used to ensure the cone remains centered. | |||

* hard black plastic ring - if the speaker has a hard plastic trim ring on the frame remove it and keep it to reuse. | |||

* graphite cones be careful - some speakers have graphite cones which crack easily, like some Pioneer brand woofers. Be extra careful when pressing on them, use minimal force. | |||

[[Category:Electronics]] | [[Category:Electronics]] | ||

[[Category:Consumer Electronics]] | [[Category:Consumer Electronics]] | ||

Latest revision as of 07:38, 28 February 2020

This guide is applied to the speaker woofer.

The foam flex ring surround may deteriorate with age and may be replaced without the need to replace the entire woofer. This requires a little cutting, scraping, cleaning, and careful application of a new foam surround using adhesive.

1. Remove speaker woofers from the cabinet.

2. Remove any large pieces of remaining foam by simply pulling them away from the cone and frame. If there is a gasket on top of the old foam, remove it with a utility knife and retain for reuse.

3. Scrape all remaining foam and glue from the frame with the utility knife or similar scraping instrument. Soften the glue and foam using rubbing alcohol or paint thinner. Scrape thoroughly and try to get as much residue removed as possible.

4. Perform a final check to ensure the foam ring will fit properly. Variances of 1/8" or less are within tolerances. If the outer lip of the foam ring is too large for the frame you may trim the outer diameter back as needed.

5. We will adhere the inner diameter of the foam ring first. Remember, the outside of the speaker cone will be glued to the inner part of the foam flex ring. The new foam flex ring will be glued to the top of the cone regardless of where the previous foam flex ring was attached.

- a) for flat lip cone: Apply an 1/8" bead of glue to the flat lip on the outer diameter of the speaker cone, not the inside ring of the foam.

- b) for angle lip cone: Apply an 1/8" bead of glue to the underside inner lip of the foam ring.

6. Apply the adhesive evenly and waste no time in attaching to the speaker cone. Do not use too much glue, the glue is formulated for this purpose and should be very effective at the correct conservative amount. Make sure the foam is aligned on the cone. Work the new edge to cone for several minutes by pressing lightly with your fingers. Careful not to slide the ring out of position. keep working your way around the ring and repeat in the same direction. Do this for 2 - 5 minutes, or until you notice the ring remains snug in that it is not pulling up with the glue, you may have to do this longer for the angle lip type of speaker. You have have to utilize a custom pressure ring, see notes below on custom pressure ring. Once firm, allow the glue to drive for at least one full hour.

7. Once dry time is observed, prepare the speaker cone for the gluing of the outer foam ring. You will press lightly and flex the cone while you observe the movement of the foam ring. You don't want to glue the outer part of the foam ring in such a way that it restricts movement of the cone or you will negatively impact the performance and sound of the woofer. This step is known as exercising the cone and will allow you a sense of the range of movement of the outer ring. The foam ring will need to be centered based on movement of the cone rather than visually by its position on metal frame. Observe the position the foam ring resides on the frame when the cone moves without scraping on the voice coil. We want the foam ring to reside at this place when glued so that the foam ring serves to allow equal and full range of movement when the speaker is operational. The ideal spot will ensure there is no contact scraping of the voice coil during movement. You may notice that the foam ring does not visually appear perfectly centered within the metal frame, however, what is more important is that it is residing where cone movement is centered and correct.

8. Slip the tip of the glue bottle between the foam ring and the speaker frame edge to apply glue between the foam ring and speaker frame. Apply the glue between the foam and frame all the way around the circumference of the speaker before pressing. Exercise the cone once again and carefully observe movement to make sure it is even, centered, and that the foam ring is at the ideal spot. Once you have confirmed the foam ring is centered start applying pressure with your fingers working your way around the edge. Press down evenly while working your way around the outer ring. Note that you will probably see some wrinkling of the new edge, and this is typical to a slight degree as it will subside as the glue dries. Give the glue an hour to dry.

9. Glue the gasket back on the speaker if it is necessary or applicable to the design, it goes over the outer diameter of the foam ring.

10. Reinstall the woofer in the speaker enclosure and reconnect the wires observing proper polarity.

done!

- custom pressure ring - this is a method to apply constant pressure to the inner foam ring glued to the cone while the glue dries.

- shimming the cone - this is not covered in this guide. It is a technique which requires removal of the dust cap so that the shim is used to ensure the cone remains centered.

- hard black plastic ring - if the speaker has a hard plastic trim ring on the frame remove it and keep it to reuse.

- graphite cones be careful - some speakers have graphite cones which crack easily, like some Pioneer brand woofers. Be extra careful when pressing on them, use minimal force.