PEX Supply Water Piping: Difference between revisions

mNo edit summary |

|||

| (4 intermediate revisions by the same user not shown) | |||

| Line 109: | Line 109: | ||

=== Can PEX be joined with solvent cement? === | === Can PEX be joined with solvent cement? === | ||

No. PEX cannot be joined with solvent cement, glues or heat fusion. PEX is installed using only mechanical fittings or compression fittings. | No. PEX cannot be joined with solvent cement, glues or heat fusion. PEX is installed using only mechanical fittings or compression fittings. | ||

| |||

[[Image:PEX16m15c.jpg|center]] | |||

| |||

== Installing PEX == | |||

One of the popular uses of PEX tubing is for hot and cold water installations in the home. PEX tubing is not glued togeather like CPVC. All fittings are mechanical fittings. PEX is also very flexible thus reducing the number of fittings necessary. The following tools and materials are necessary: | |||

* Fittings | |||

* PEX tubing designed for the job | |||

* Tubing cutter | |||

* Ring crimper | |||

* crimp rings | |||

* "Go/No-Go" gauge | |||

* Crimp ring removal tool | |||

Measure out the length of PEX you will need for installation and cut it with the PEX tubing cutter. These pliers are especially designed for PEX and should always be used. An unclean cut with burrs or that is not straight may result in leakage. Make your cut to the desired length, keeping in mind a little slack is needed for heat expansion and cold contraction, then slip a copper crimp ring onto the pipe. | |||

Allowances must be made for ever 10 degrees of change in temperature. PEX will contract one inch every 100 feet of pipe with every 10° of temperature change. Offset this by making a loop in the PEX that is no more than 8 times the diameter of the tubing. | |||

Insert the tubing into the piper fitting. It should bottom out on the shoulder of the fitting. Slide the copper crimp ring up so that it is 1/8" to 1/4" away from the tubing. | |||

Crimp the copper crimp ring with the ring crimper, insuring that the crimper is at a 90 degrees angle from the crimp ring. Close the crimp tool fully on the crimp ring. | |||

Now, test the crimp with the Go/No-Go gauge. The Go-gauge should slide onto the fitting with ease. It may be tight where the crimping tool has marked the crimping surface during the crimping operation. The No-Go gauge must not slide over the fitting. If it does, the tubing must be recut and the joint made once again. | |||

Avoid a leak by carefully inspecting your work. Observe the tubing and look for any of the following conditions: | |||

* Ring crimped over the end of the tubing. Not enough ribs covered. | |||

* Crimp tool not at 90 degrees. Plastic dented and not enough rib coverage. | |||

* Copper crimp ring not completely covered by crimping tool. Ring is distorted with a non uniform crimp. | |||

* Tubing not squarely cut. Does not cover ribs of fitting. | |||

Correct any of the defects mentioned above. | |||

Straps and hangers are used to secure PEX line at each 6 foot length. It must be supported at least every 32 inches if tubing is installed alongside a joist. When run vertically, it will require support at every floor level. When installing, always leave slack in the tubing to allow for contraction. The support hangers should not be so tight that they will restrict movement of the PEX. | |||

| |||

== PEX Fittings, Valves, and Materials == | |||

[[Connecting Fixtures to a PEX Residential Water System]] discusses connecting sink, toilet, bath, laundry, and other common residential fixtures to PEX plumbing. This is especially useful as a reference for people replacing old plumbing in a home with modern PEX plumbing. | |||

HydroPEX Fittings are clamp/crimp style fittings, ProPEX are Expansion Style PEX Fittings, and there are Sharkbite Compression style PEX fittings. To make clamp connections the Clamp tool and stainless clamps are required, to make crimp connections a crimp tool and copper crimp rings are required, finally to make Propex connections a Wirsbo ProPEX tool and ProPEX Rings are required. The Sharkbite Compression fittings are not recommended by some plumbers due to perceived limited longevity. | |||

There are four basic PEX connection systems. The first is the Wirsbo ProPEX system that requires the ProPEX expander tool, ProPEX rings and ProPEX fittings. This connection system can only be used with PEX-a tubing. The second is the stainless steel clamp system that requires a clamping tool, stainless steel clamps, and barbed PEX fitting (HydroPEX). Third is the copper crimp ring system that requires a crimping tool, copper crimp rings, and barbed PEX fittings (HydroPEX). Last is the Sharkbite, compression-style, fittings that do not require a special tool. | |||

HydroPEX fittings may be used with the stainless steel clamping system or the copper crimp ring system. These PEX fittings may be used for PEX Plumbing. They allow you to make connections while using PEX Tubing. | |||

ProPEX Fittings are expansion style fittings. These PEX Fittings are manufactured by Uponor, formerly known as Wirsbo. The fittings are widely used throughout the US and Europe for PEX Tubing connections. | |||

SharkBite Push-Fit Fittings are designed to simplify pipe installation. The fittings allow users to connect pipe in seconds with ease. | |||

Instant push-fit connection for increased ease of use. Certified to 200 psi and 200°F (93°C). | |||

The Viega PEX Press fitting system meets strict ASTM standards in addition to UPC and international codes for potable water systems. The high quality bronze PureFlow PEX Press fittings are more resistant to corrosion and stress cracking. | |||

| | ||

| Line 115: | Line 173: | ||

| | ||

[[Category:Construction]] | |||

[[Category:Plumbing]] | [[Category:Plumbing]] | ||

Latest revision as of 14:45, 5 December 2012

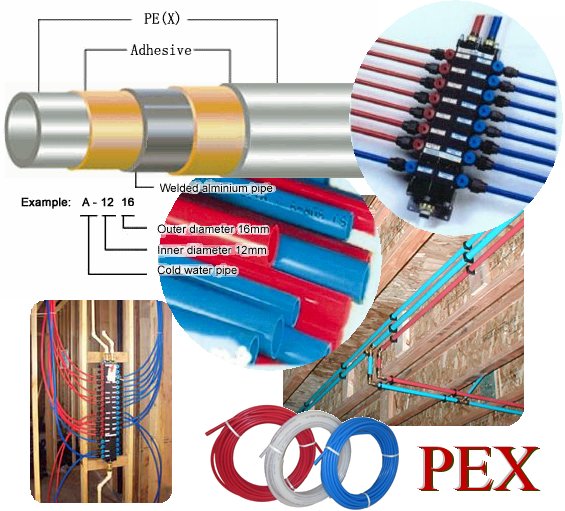

Cross-linked polyethylene (PEX) is a form of polyethylene with cross-links.

PEX is made by a process that forms links between polyethylene molecules to create bridges (thus the term "cross-linked). This resulting material is more durable under temperature extremes, chemical attack, and better resists creep deformation, making PEX an excellent material for hot water and other applications. It doesn’t corrode or develop pinhole leaks, is chlorine-resistant, scale-resistant, and has fewer fittings, connections, and elbows than rigid plastic and metallic pipe.

Cross-linked polyethylene (PEX) is a high-temperature, flexible plastic (polymer) pipe. The cross-linking raises the thermal stability of the material under load. Thus, the resistance to environmental stress cracking, creep, and slow crack growth are greatly improved over polyethylene.

The caveat to PEX plumbing is the long-term effect of chlorinated water on the vinyl walls in the tubing remains unknown for certain.

PEX pipe is approved for potable hot- and cold-water plumbing systems and hot-water (hydronic) heating systems in all model plumbing and mechanical codes across the U.S. and Canada. PEX piping systems are durable, provide security for safe drinking water, and use reliable connections and fittings. There are currently about ten domestic producers of quality PEX piping.

Brass fittings and couplings and polyethylene tees and elbows are available. Fittings are available in both mechanical compression and crimping styles, depending on application and manufacturer. In addition to domestic water supply systems, PEX tubing can be used for floor or wall radiant heating, and snow and ice melting systems in sidewalks and driveways.

PEX tubing is light weight, and it can withstand operating temperatures of up to 200° F (93° C). It is flexible and can easily be bent around corners and obstacles, and through floor systems. Sizes of PEX tubing range from 3/8-inch to over 2 inches.

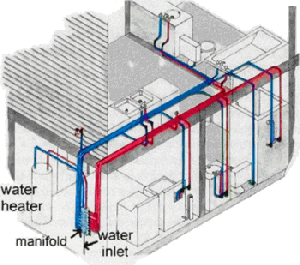

Complete PEX House Plumbing System

PEX Manifold

The manifold is the primary hub for hot and cold water in a home with all PEX plumbing. A manifold Pex plumbing system allows for easy maintenance and better water distribution over traditional systems. Think of the central manifold the same way as your electrical breaker box, except for water. You have a central command with NO connectors between the manifold and appliances, the largest source of weakness in traditional systems. Proven technology over decades, it is finally changing the way we plumb.

A popular PEX Manifold is the Vanguard Manifold Manabloc for home plumbing systems. The MANABLOC control unit has individual shut-off valves to allow the homeowner to turn off a single fixture without effecting the rest of the home. The valves are labeled to indicate which fixture it controls in the home.

The system distributes water efficiently and economically. By sizing the lines according to the demand of each fixture, homeowners enjoy much faster hot water delivery which results in significant water and energy savings. The 1 1/4" reservoir in the MANABLOC maintains more consistent supply of water pressure reducing the potential for drastic temperature changes at fixtures; even when other fixtures are operated simultaneously. The performance of a conventional plumbing system during multiple fixture operation can't compare to a MANABLOC system.

PEX FAQ

What are recommended uses for PEX?

PEX 's flexibility and strength at temperatures ranging from below freezing up to 200 degrees Fahrenheit makes it an ideal piping material for hot and cold water plumbing systems, service lines, hydronic radiant heating systems, snow melting applications, ice rinks and refrigeration warehouses.

Why is PEX an excellent piping material for plumbing?

PEX is ideally suited for potable water plumbing applications. It is flexible, making it easy to install and service. PEX is able to withstand the high and low temperatures found in plumbing and heating applications, and is highly resistant to chemicals found in the plumbing environment. Flexible systems are quieter than rigid piping. The smooth interior will not corrode which can affect other materials long term pipe flow characteristics. PEX is also very freeze- break resistant. PEX systems have fewer joints and are easier to install providing a lower cost installation over traditional plumbing materials.

Can PEX be used for underground cold-water service applications?

Yes. Although the high temperature resistance of PEX makes it particularly suitable for hot and cold interior plumbing applications, it also makes an excellent underground water service piping. The new AWWA C904 standard also applies to PEX used in this application. PEX can be installed using the same fittings recommended for copper tube sized SDR-9 polyethylene tubing.

Can PEX be used for aboveground outdoor applications?

No. PEX is currently designed for indoor and buried applications only and is not recommended for outdoor, aboveground use. Short exposures to sunlight during construction are permissible, but should not exceed the manufacturer’s recommendations. PEX should be stored under cover, shielded from direct sunlight or in the original packaging. In the future, PEX products rated for outdoor use may be developed.

Can PEX save me money?

Yes. PEX saves money in many ways. For the installer, PEX tubing is competitively priced. Installation of flexible systems is fast because of the easy handling of the tubing and PEX installation requires fewer directional fittings. Since most plumbing problems occur at joints, fewer fittings also reduce the chances for leaks and callbacks, saving the installer even more time. The homeowner saves in the cost of the installed system, and can reduce utility costs in some layouts .

Home run or manifold plumbing systems utilizing PEX tubing can substantially reduce water and energy consumption in a home. The home-run concept provides dedicated direct lines from the manifold to the fixtures, reducing the amount of water that must be purged from the lines to get hot water at the fixture. Direct lines can be sized to the fixture requirements, further reducing the amount of time to wait for hot water. Faster hot water delivery reduces water waste and the amount of times the water heater must cycle to supply hot water.

What is the expected performance of PEX water distribution systems?

PEX is designed and tested to perform as well or better than any other material approved for hot and cold-water distribution systems. For indoor plumbing applications, PEX is expected to perform as long as copper, CPVC or any other approved plumbing distribution materials.

What joining systems are available?

There are several methods of connecting PEX, all of which involve mechanical fittings. There are two approved standard specifications for PEX connections: ASTM F 1807 and ASTM F 1960. Both reference mechanical insert fittings. The crimp fittings specified in ASTM F1807 are the most widely used. Other fitting systems, including insert and outside diameter compression fittings, are also available. PEX cannot be joined by solvent cement or heat fusion methods.

How long can PEX be exposed to sunlight?

PEX tubing is not intended for outdoor applications and must be stored in a covered environment not exposed to direct sunlight. Refer to manufacturer’s instructions as to how long your pipe can have UV or sunlight exposure.

What are temperature limitations for PEX?

PEX tubing can be used up to 200° Fahrenheit for heating applications. For plumbing, PEX is limited to 180° F. Temperature limitations are always noted on the print line of the PEX tubing.. PEX systems are tested to and can be used with standard T and P relief valves that operate at 210” F and 150 psi.

How are PEX systems tested for leaks?

PEX plumbing and radiant heating systems can be pressure tested using water to check for leaks. Follow manufacturer's instructions.

How soon after installation can you pressure test a PEX tubing installation?

Most PEX plumbing systems can be tested immediately after the installation is complete but follow manufacturer’s directions.. There is no wait time for glue to dry or joint to cool off. Manufacturer's instructions should be followed in cold climates.

What sizes, lengths and packaging options of PEX are available?

PEX is available in 1/4" through 1" CTS (Copper Tube Size) and is packaged in coils or 20' straight lengths. Some manufacturers tubing is color-coded for easy identification of hot and cold lines. Coil lengths generally run to a maximum of 1000' and are available in a variety of shorter lengths.

Is flexible PEX plumbed differently than rigid material plumbing systems?

Yes, the flexibility of PEX allows many directional changes to be made without fittings. PEX systems are sized in the same manner as copper or CPVC CTS plumbing systems. PEX piping is also used in high performance manifold plumbing systems that takes advantage of the flexibility and cost effective.

What are manifold plumbing systems?

Manifold, parallel or home-run plumbing systems are much like a breaker box for the electrical system in the home. The manifold provides a common location from which all the plumbing fixtures are supplied. Some high-end manifolds also feature fixture shut-off valves allowing the user to shut off the water to individual fixtures from one location. Others are semi-home run manifolds or termination manifolds, which may feed the plumbing requirements for a room or set of rooms and reduce the number of fittings required in the plumbing system.

How are PEX systems sized?

PEX systems are sized just like other CTS plumbing materials such as copper or CPVC when used in a trunk-and-branch installation. PEX can be sized in manifold systems to meet the specific demands of each fixture, reducing water and energy waste in the home.

Is the thermal expansion/contraction of PEX a problem?

No. While PEX expands more than other plumbing materials, directional changes made with the tubing and some slack in the tubing during installation accommodate the expansion and contraction of the system if properly installed.

Is PEX freeze-break resistant?

PEX piping is freeze damage resistant and can expand and contract as water freezes and thaws within the tubing. No tubing material is freeze-break proof, however, and PEX should be installed using the same locally-prescribed insulation requirements to prevent freezing of any plumbing system.

How do I thaw PEX lines?

When water freezes inside PEX tubing, it can be thawed using a hair dryer, warm wet rags or heat tape, taking care not to overheat the tubing beyond the maximum recommended temperature.

Can PEX be joined with solvent cement?

No. PEX cannot be joined with solvent cement, glues or heat fusion. PEX is installed using only mechanical fittings or compression fittings.

Installing PEX

One of the popular uses of PEX tubing is for hot and cold water installations in the home. PEX tubing is not glued togeather like CPVC. All fittings are mechanical fittings. PEX is also very flexible thus reducing the number of fittings necessary. The following tools and materials are necessary:

- Fittings

- PEX tubing designed for the job

- Tubing cutter

- Ring crimper

- crimp rings

- "Go/No-Go" gauge

- Crimp ring removal tool

Measure out the length of PEX you will need for installation and cut it with the PEX tubing cutter. These pliers are especially designed for PEX and should always be used. An unclean cut with burrs or that is not straight may result in leakage. Make your cut to the desired length, keeping in mind a little slack is needed for heat expansion and cold contraction, then slip a copper crimp ring onto the pipe.

Allowances must be made for ever 10 degrees of change in temperature. PEX will contract one inch every 100 feet of pipe with every 10° of temperature change. Offset this by making a loop in the PEX that is no more than 8 times the diameter of the tubing.

Insert the tubing into the piper fitting. It should bottom out on the shoulder of the fitting. Slide the copper crimp ring up so that it is 1/8" to 1/4" away from the tubing.

Crimp the copper crimp ring with the ring crimper, insuring that the crimper is at a 90 degrees angle from the crimp ring. Close the crimp tool fully on the crimp ring.

Now, test the crimp with the Go/No-Go gauge. The Go-gauge should slide onto the fitting with ease. It may be tight where the crimping tool has marked the crimping surface during the crimping operation. The No-Go gauge must not slide over the fitting. If it does, the tubing must be recut and the joint made once again.

Avoid a leak by carefully inspecting your work. Observe the tubing and look for any of the following conditions:

- Ring crimped over the end of the tubing. Not enough ribs covered.

- Crimp tool not at 90 degrees. Plastic dented and not enough rib coverage.

- Copper crimp ring not completely covered by crimping tool. Ring is distorted with a non uniform crimp.

- Tubing not squarely cut. Does not cover ribs of fitting.

Correct any of the defects mentioned above.

Straps and hangers are used to secure PEX line at each 6 foot length. It must be supported at least every 32 inches if tubing is installed alongside a joist. When run vertically, it will require support at every floor level. When installing, always leave slack in the tubing to allow for contraction. The support hangers should not be so tight that they will restrict movement of the PEX.

PEX Fittings, Valves, and Materials

Connecting Fixtures to a PEX Residential Water System discusses connecting sink, toilet, bath, laundry, and other common residential fixtures to PEX plumbing. This is especially useful as a reference for people replacing old plumbing in a home with modern PEX plumbing.

HydroPEX Fittings are clamp/crimp style fittings, ProPEX are Expansion Style PEX Fittings, and there are Sharkbite Compression style PEX fittings. To make clamp connections the Clamp tool and stainless clamps are required, to make crimp connections a crimp tool and copper crimp rings are required, finally to make Propex connections a Wirsbo ProPEX tool and ProPEX Rings are required. The Sharkbite Compression fittings are not recommended by some plumbers due to perceived limited longevity.

There are four basic PEX connection systems. The first is the Wirsbo ProPEX system that requires the ProPEX expander tool, ProPEX rings and ProPEX fittings. This connection system can only be used with PEX-a tubing. The second is the stainless steel clamp system that requires a clamping tool, stainless steel clamps, and barbed PEX fitting (HydroPEX). Third is the copper crimp ring system that requires a crimping tool, copper crimp rings, and barbed PEX fittings (HydroPEX). Last is the Sharkbite, compression-style, fittings that do not require a special tool.

HydroPEX fittings may be used with the stainless steel clamping system or the copper crimp ring system. These PEX fittings may be used for PEX Plumbing. They allow you to make connections while using PEX Tubing.

ProPEX Fittings are expansion style fittings. These PEX Fittings are manufactured by Uponor, formerly known as Wirsbo. The fittings are widely used throughout the US and Europe for PEX Tubing connections.

SharkBite Push-Fit Fittings are designed to simplify pipe installation. The fittings allow users to connect pipe in seconds with ease. Instant push-fit connection for increased ease of use. Certified to 200 psi and 200°F (93°C).

The Viega PEX Press fitting system meets strict ASTM standards in addition to UPC and international codes for potable water systems. The high quality bronze PureFlow PEX Press fittings are more resistant to corrosion and stress cracking.