Difference between revisions of "Grade Markings for Steel Fasteners"

m |

m |

||

| Line 7: | Line 7: | ||

* Bolts,Screws,Studs with 5 symmetrical tick marks spaced 72° on the head = Grade 7 | * Bolts,Screws,Studs with 5 symmetrical tick marks spaced 72° on the head = Grade 7 | ||

* Bolts,Screws,Studs with 6 symmetrical tick marks spaced 60° on the head = Grade 8 | * Bolts,Screws,Studs with 6 symmetrical tick marks spaced 60° on the head = Grade 8 | ||

| + | |||

| + | Grade 8 fasteners are the strongest with a minimum tensile strength of 150ksi for all diameters from ¼ inch through 1-1/2 inches. They are required to be heat-treated, quenched, and tempered. | ||

| + | |||

| + | [[File:WikiSAEFastenerDesignations.png]] | ||

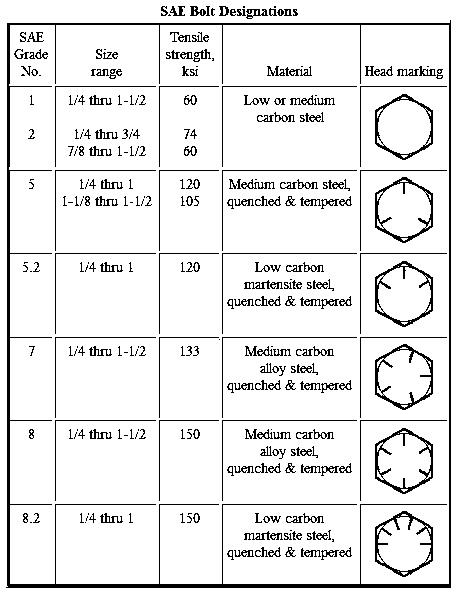

The '''Society of Automotive Engineers (SAE)''' has a standard called SAE J429 Mechanical And Material Requirements for Mechanical Fasteners. The standard introduces a designation system based on numbers where increasing numbers indicate increasing tensile strength. Another organization, ASTM International, formerly known as '''American Society for Testing and Materials''', is an international standards organization that develops and publishes voluntary consensus technical standards. ASTM fastener standards specify and test the properties of mechanical fasteners such as bolts, nuts, screws, and other hardware fasteners. | The '''Society of Automotive Engineers (SAE)''' has a standard called SAE J429 Mechanical And Material Requirements for Mechanical Fasteners. The standard introduces a designation system based on numbers where increasing numbers indicate increasing tensile strength. Another organization, ASTM International, formerly known as '''American Society for Testing and Materials''', is an international standards organization that develops and publishes voluntary consensus technical standards. ASTM fastener standards specify and test the properties of mechanical fasteners such as bolts, nuts, screws, and other hardware fasteners. | ||

| + | Inch-series fasteners utilize standards ASTM A307, ASTM A354, and ASTM A193 | ||

| − | |||

[[Category:Construction]] | [[Category:Construction]] | ||

Revision as of 07:45, 12 June 2019

Bolts (non-metric) and all fasteners are made to meet certain strength requirements and have a grade or ASTM rating. Special markings on screw heads and nuts identify the fastener's grade. Bolts and screws have a grade and manufacturer identification marking. Screws and bolts above 1/4" are typically marked on the top of their head unless Grade 2.

Bolt Grade Markings and Tensile Strength - SAE and ASTM.

- Bolts,Screws,Studs with no tick marks on the head = Grade 2

- Bolts,Screws,Studs with 3 symmetrical tick marks spaced 120° on the head = Grade 5

- Bolts,Screws,Studs with 5 symmetrical tick marks spaced 72° on the head = Grade 7

- Bolts,Screws,Studs with 6 symmetrical tick marks spaced 60° on the head = Grade 8

Grade 8 fasteners are the strongest with a minimum tensile strength of 150ksi for all diameters from ¼ inch through 1-1/2 inches. They are required to be heat-treated, quenched, and tempered.

The Society of Automotive Engineers (SAE) has a standard called SAE J429 Mechanical And Material Requirements for Mechanical Fasteners. The standard introduces a designation system based on numbers where increasing numbers indicate increasing tensile strength. Another organization, ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards. ASTM fastener standards specify and test the properties of mechanical fasteners such as bolts, nuts, screws, and other hardware fasteners.

Inch-series fasteners utilize standards ASTM A307, ASTM A354, and ASTM A193