Difference between revisions of "Home Central Air Conditioner"

(→Primary Components) |

|||

| Line 1: | Line 1: | ||

== Primary Components == | == Primary Components == | ||

| + | |||

| + | The residential air conditioner has two units, an in-house Air Handler Unit and an outside Condenser Unit. The two units are connected with two lines. The system is considered to have three primary parts: | ||

* Outdoor Condenser | * Outdoor Condenser | ||

| Line 5: | Line 7: | ||

* Thermostat | * Thermostat | ||

| + | Central air conditioners circulate cool air through a system of supply and return ducts. The cooled air becomes warmer as it circulates through the home; then it flows back to the central air conditioner through return ducts and registers. | ||

| + | |||

| + | A central air conditioner is either a split-system unit or a packaged unit. In a split-system central air conditioner, there is an outdoor condenser and compressor, and an indoor evaporator, also known as the a-coil. The a-coil is typically installed in the same unit as the heater, but at the end where it is the last part air flows though before going into ductwork. If your home already has a furnace but no air conditioner, a split-system is the most economical central air conditioner to install. | ||

| + | |||

| + | '''Split System Central Air'''<BR> | ||

[[File:Home-Central-Air-Conditioner-Diag01.png]] | [[File:Home-Central-Air-Conditioner-Diag01.png]] | ||

| Line 21: | Line 28: | ||

* (3) coolant is hot, high pressure gas | * (3) coolant is hot, high pressure gas | ||

* (4) coolant is hot, high pressure liquid | * (4) coolant is hot, high pressure liquid | ||

| + | |||

| + | Alternatively, a packaged unit has the evaporator, condenser, and compressor all located in one box, which usually is placed on a roof or on a concrete slab next to the house's foundation. They will not be discussed much here. | ||

== Refrigerant == | == Refrigerant == | ||

| Line 53: | Line 62: | ||

* Large Line = Suction Line, which feels cold to the touch while unit is operating in AC. It carries the coolant as a gas and this line should be insulated the entire length to help prevent the coolant from heating up due to the exterior temperature. | * Large Line = Suction Line, which feels cold to the touch while unit is operating in AC. It carries the coolant as a gas and this line should be insulated the entire length to help prevent the coolant from heating up due to the exterior temperature. | ||

| − | * Small Line = Liquid Line (also called the pressure line), which feels hot to the touch while unit is operating in AC. Carries liquid coolant between the two units, this line gets very hot when operating due to the coolant being put under pressure. This line should not be insulated. | + | * Small Line = Liquid Line (also called the pressure line or pushing line), which feels hot to the touch while unit is operating in AC. Carries liquid coolant between the two units, this line gets very hot when operating due to the coolant being put under pressure. This line should not be insulated. |

| − | + | ||

| − | + | ||

== Troubleshooting == | == Troubleshooting == | ||

Revision as of 13:55, 28 June 2012

Contents

Primary Components

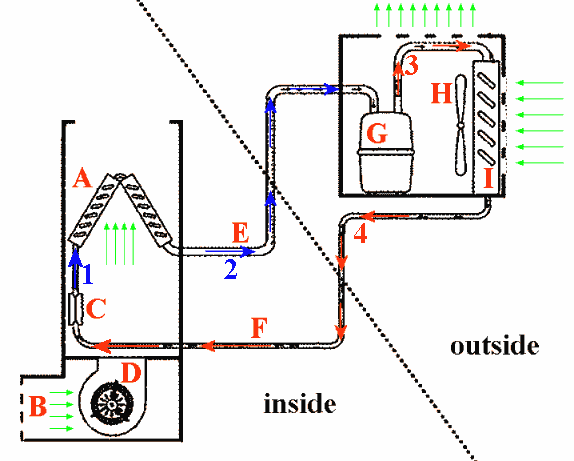

The residential air conditioner has two units, an in-house Air Handler Unit and an outside Condenser Unit. The two units are connected with two lines. The system is considered to have three primary parts:

- Outdoor Condenser

- Indoor Evaporator (A-Coil)

- Thermostat

Central air conditioners circulate cool air through a system of supply and return ducts. The cooled air becomes warmer as it circulates through the home; then it flows back to the central air conditioner through return ducts and registers.

A central air conditioner is either a split-system unit or a packaged unit. In a split-system central air conditioner, there is an outdoor condenser and compressor, and an indoor evaporator, also known as the a-coil. The a-coil is typically installed in the same unit as the heater, but at the end where it is the last part air flows though before going into ductwork. If your home already has a furnace but no air conditioner, a split-system is the most economical central air conditioner to install.

- (A) Evaporator Coil (A-Coil)

- (B) Air Filter

- (C) Expansion Device

- (D) Blower Fan

- (E) Suction Line

- (F) Liquid Line (Pressure Line)

- (G) Compressor

- (H) Fan

- (I) Outside Condensing Coil

- (1) coolant is cold, low pressure liquid

- (2) coolant is cold, low pressure gas

- (3) coolant is hot, high pressure gas

- (4) coolant is hot, high pressure liquid

Alternatively, a packaged unit has the evaporator, condenser, and compressor all located in one box, which usually is placed on a roof or on a concrete slab next to the house's foundation. They will not be discussed much here.

Refrigerant

There are 2 different types of air conditioning refrigerant currently used in residential cooling systems. R-22, commonly referred to a Freon and R410A, a blend considered to be more environmentally friendly, sometimes called Puron.

R-22

R-22 also known as Freon has been used for decades as the refrigerant in central air conditioning systems. However it has been linked to Ozone depletion and has therefore been banned from being manufactured after the year 2010.

R410A

Refrigerant of 4xx series, e.g. R-404a are non azeotrope type refrigerants, EXCEPT for R-410.

R-410 is a near azeotrope mixture. Azeotrope refrigerants consist of more than one blend of refrigerants, but it acts like a single refrigerant. Non azeotrope refrigerants on the other hand, DO NOT act like a single refrigerant.

You cannot add a charge to a non-azeotrope refrigerant system. If low, the remaining refrigerant needs to be completely evacuated and the system has to be charged again from zero. This is because of the physical properties of the different chemicals being lost from the system at different rates. The blends will be lost from the system at different proportions due to different boiling temperatures, whenever there is a leakage in the non azeotrope refrigerant.

Azeotrope, or near azeotrope blends will act as a single refrigerant, and therefore, may be topped up in case of refrigerant leakage. R-410A, just like R-22 can be topped up.

Pump Down Procedure

You will need a set of refrigeration gauges and a means of closing whatever types of service valves are on your unit. You will also need to know what order in which to close those valves and what the readings on the gauges are telling you. The pump down procedure only takes a couple of minutes.

There are two valves at the condenser, one valve for the suction line and one valve for the liquid line. Close the liquid line valve and turn the air conditioning on. The compressor pumps all the refrigerant into the condenser coils. Watch the gauges carefully and when the pressure gets to zero on the gauges quickly close the suction line valve to trap the refrigerant in the condenser. Now quickly turn the compressor off. This saves using refrigerant unnecessarily because the same refrigerant in the system can be reused for the new evaporator coil or air handler.

After the new evaporator coil or air handler is installed you need to evacuate the new part of the system. When evacuation is completed open the valves to allow the refrigerant into the new part of the system. To make sure the charge is correct use the gauges and the superheat method or subcooling to ensure the proper amount of refrigerant is in the system.

Refrigerant Line Sets

The coolant line set runs externally to connect the separate air handler and exterior compressor unit and transport the coolant between the two components. This line-set consists of two copper lines. Line sets consist of two semi-flexible copper pipes to connect the outdoor air conditioner or heat pump to the indoor evaporator coil. The smaller pipe is called the liquid line. The larger pipe is referred to as the suction line, and includes insulation.

- Large Line = Suction Line, which feels cold to the touch while unit is operating in AC. It carries the coolant as a gas and this line should be insulated the entire length to help prevent the coolant from heating up due to the exterior temperature.

- Small Line = Liquid Line (also called the pressure line or pushing line), which feels hot to the touch while unit is operating in AC. Carries liquid coolant between the two units, this line gets very hot when operating due to the coolant being put under pressure. This line should not be insulated.

Troubleshooting

Blowing Warm Air & A-Coil Not Frozen

Possible Causes:

- Compressor Not Running

- Low on Coolant

Low on coolant. Refrigerant doesn't require periodical charging. It is not a consumable item within an air conditioning unit, unless, there is a leak within the system. Given that it worked previously, and now it is not working, it is likely there is a leak in the system.

There are two copper lines that run between the outdoor compressor to the indoor unit (a-coil) and of those two lines the large one should feel very cold, with some degree of condensation present, while the small line should feel warm. If both of these lines do not feel different from the ambient air temperature, it is also a sign that (a) insufficient coolant present or (b) compressor not pumping coolant.

Be sure to check the electrical breaker for the outdoor compressor. If that compressor is not running, then this will also cause the symptoms.

Blowing Warm Air & A-Coil Iced Over

The A-Coil can freeze up, building up ice and lowering efficiency. When completely frozen over it will not function. One cause if this happening is lack of circulation, due to the fan malfunctioning or insignificant fan speed, or and undersized blower. Increasing air circulation though the system can prevent the A-Coil from freezing over.

If the air conditioner is not properly charged, such as too much or little coolant (pressure) then the system may operate in an inefficient way and also cause the A-Coil to freeze up.

Turn off the unit and allow the A-Coil to thaw completely. Make sure the tray below the A-Coil is not pooling with water. It should be able to drain out a hose.

Refrigerant Leak Detection

A leak in the air conditioner tubes will pose the threat of refrigerant loss and finally, no cooling.

There are three common leak detection methods at end user level.

- Soap test

- Electronic leak detector

- UV light test

Electronic leak detector is the most widely used method nowadays, with lightweight construction, and accurate pin-pointing of the leak position on the tube, or other air conditioner parts.

Treatment for leaks is either part replacement, or repair by tube soldering, or welding.