Restaurant Hood Systems and Fire Suppression: Difference between revisions

mNo edit summary |

|||

| Line 1: | Line 1: | ||

Restaurant and kitchen hood fire suppression systems are required by law to be inspected, serviced, tested and certified at semi annual intervals. Outdated equipment must be made current to comply with fire code laws. | Restaurant and kitchen hood fire suppression systems are required by law to be inspected, serviced, tested and certified at semi annual intervals. Outdated equipment must be made current to comply with fire code laws. | ||

[[Image:rangesystem16.png]] | |||

== Restaurant Grease Hood == | == Restaurant Grease Hood == | ||

Revision as of 13:07, 3 July 2008

Restaurant and kitchen hood fire suppression systems are required by law to be inspected, serviced, tested and certified at semi annual intervals. Outdated equipment must be made current to comply with fire code laws.

Restaurant Grease Hood

terminology keywords: Stainless Steel, Kitchen Exhaust Hood, Grease Hood, Galvanized Restaurant Grease Hood, Box Exhaust Canopy

A Kitchen Ventilation Hood is an air-intake device that is first, designed to capture vapors, fumes, smoke, steam, heat or odors from commercial food and heat-processing equipment, and second remove the captured matter by means of a mechanical exhaust system. A Kitchen Ventilation Hood is required when a Food Processing Establishment uses Heat-Processing equipment for food or utensils which produces grease, vapors, steam, fumes, smoke, or odors. A Type 1 Hood is a Hood that is designed for collecting and removing vapors, steam, fumes, odors and GREASE and SMOKE produced by Heat-Processing Equipment while a Type 2 Hood is a Hood that is designed for collecting and removing vapors, steam, fumes, and odors produced by Heat-Processing Equipment. A Type II Hood Should NOT be used over Heat-Processing Equipment that produces Grease or Smoke.

The National Fire Code (NFC) dictates that the Hood should be 6 inches larger on all sides compared to all of the equipment that is under it.

Canopy hoods are now commonly constructed of 16 and 18 gauge steel. Joints are welded liquid tight without seams, utilizing an automatic wire feed mig welder.

Hood to Fan Ductwork

terminology keywords:

Code in many states requires 18 gauge ductwork if it is steel, 22 gauge if it is stainless. Galvanized ductwork can be at a minimum gauge of 18 as long as it can be welded. 16 gauge is sometimes used because it is easier to weld the seams. Welded grease tight seams are required; all external seams to be welded liquid tight.

Some good quality duct work has integral grease troughs run the length of the hood with removable grease catch cups. A common type of duct work inside the building (not exposed to weather) is 16 gauge hot rolled carbon steel with all seams and joints welded liquid tight. Exterior ductwork (exposed to weather) is 16 gauge galvanized steel fabricated in the same manner.

Exhaust duct to hood connections should use a bolt/flange type with high temperature (1500 degree) gasket. The ductwork should be sized to provide a minimum of 1500 fpm and a maximum of 2200 fpm air flow.

The Uniform Mechanical Code states that a Type II Hood must have a duct that is constructed of rigid metallic materials of al least 0.024-inch (.0.61) (No.24 gage) thick. The Uniform Mechanical Code states that a Type I Hood must have a duct that is specifically designed for Grease laden air. The duct shall be constructed of at least. o55-inch-thick (1.40mm) ( No. 16 manufacture's standard gage) steel or stainless steel at least .044 inch (1.10mm) in thickness continuously welded and water tight.

Hood Exhaust Fan

terminology keywords: Upblast Exhaust Fan, Exhaust Vent, Direct Drive Centrifugal Upblast Exhaust Fan

Make Up Air Supply Fan

terminology keywords: Return Air, Make Up Air Vent

Make-up Air (MUA) Fans blow air into the facilities to compensate (make-up) for the air being pulled out by the Exhaust Fan.

Hood Fire Suppression

terminology keywords: Ansul Suppression System, Wet Chem, Piro-Chem, Range Guard, Pre-Engineered Fire Suppression System

Fire suppression system is required in all Type I Hood applications. The hood Fire Suppression system can be automatically actuated via fusible links or manually actuated via manual pull stations.

New UL 300 compliant wet chemical fire suppression systems are now required to be installed for the protection of the hood plenum area. Most modern fire suppression systems include a mechanical gas shut-off valve (mentioned below) and an electronic micro switch is supplied with the system. A Plenum is an enclosure that is designed to contain Exhaust or Supply Air of different pressure levels for removal or delivery.

A pre-engineered fire suppression system is a utility shut down and extinguishing agent distribution system that is designed for protecting the hood, plenum, exhaust duct, grease filters, and cooking appliances from grease fires. Gas and Electricity needs to be shut down when the Fire Suppression system actuates. Depending on local and state codes, Supply and Exhaust Fans or other equipment may also be required to shut down upon the Fire Suppression system actuation.

Gas Valve Cut Off

terminology keywords: Gas Valve, Gas Valve Disconnect, Mechanical Shutoff Valve, Ansul Gas Valve

Shuts off gas to cooking equipment in the event of fire. A gas shut off valve is required anytime that gas is used to power cooking equipment under the hood in which a Fire Suppression System is installed. An electricity shut off valve rule also applies the same way.

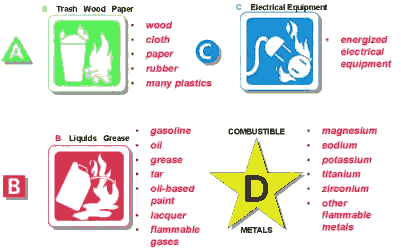

Portable Fire Extinguisher

terminology keywords: Potassium Acetate Agent

Fire extinguishers designed specifically for kitchens are now available from most suppliers. A survey prepared by the National Association of Fire Equipment Distributors recently revealed that hand operated portables extinguished over 90% of the fire incidents in commercial facilities. In most cases the fire was completely extinguished before fire department personnel arrived on the scene.