Two-Stage Propane System

First stage regulator: adjust for any differences in tank pressure, installed at or on the tank, decreases the pressure between that tank and its service line to 10 PSIG .

Second stage regulator: located at the house, decreases the propane pressure to the lines inside the home at safe and appropriate levels for appliances, usually an equivalent pressure of about 11" W.C.

The brand RegO aka Rego LPG tank valves and regulators are very common in the Midwestern United States. An example is the Rego LV3403TR First Stage High Pressure Regulator .

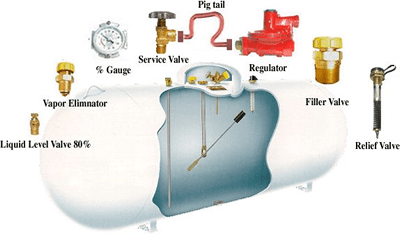

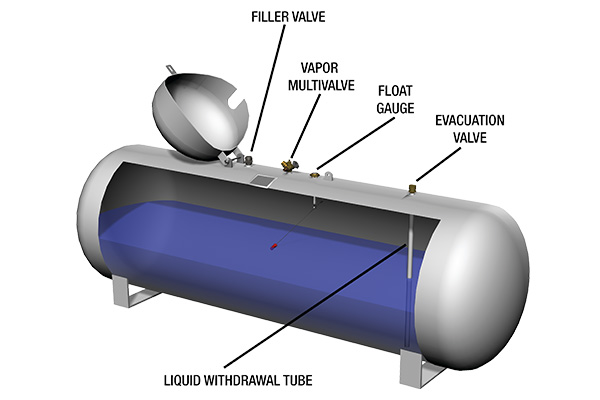

- Fill valve: Provides the attachment point from the delivery truck and has a safety feature that only allows flow into the tank, referred to as a back check.

- Relief valve: Safety valve that monitors the container’s pressure and allows excess pressure to vent in an over-pressure situation.

- Service valve: The primary way propane vapor is released from the container.

- Float gauge: Indicates the liquid level in a container, typically expressed by percent of container size.

- Fixed liquid level gauge: This device is a fixed tube designed specifically for the type and size of container. It indicates maximum allowable liquid level in a container, typically at 80 to 85 percent of container size.

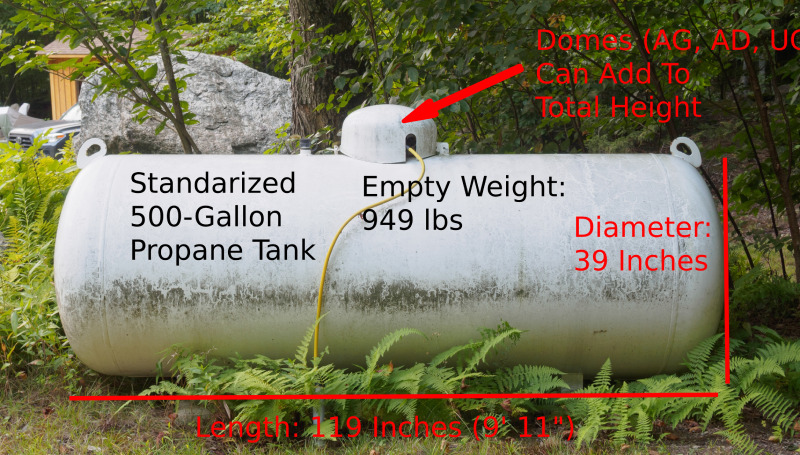

A 500-gallon propane tank weights 949 lbs and when 400 gallons of propane is added the weight goes up to 2593 lbs.

Tank to house line: For residential runs from tank to house of 150 feet or less it is common to use 3/4 inch outer diameter size of propane line. Copper Pipes are Best for Above Ground Tank line runs while steel pipes are commonly used for underground setups.