Home Plumbing Connector Types

Fitting Examples

There are just a few examples of the huge diversity of plumbing fittings. In residential plumbing consider all of the different pipe materials available and all of the different ways they can be connected. Specific fixtures in the home have their own specific connection type, such as the water supply to a toilet. Finally, there are companies that make their own proprietary fittings and connectors. Proprietary types are not discussed and their use is discouraged.

The most typical connections between like building materials are made and some examples include: Copper pipes are typically connected with copper fittings that are smooth inside and soldered. You solder a fitting to a copper pipe. Steel (Galvanized) and Iron (Black) are sealed with Teflon (PTFE) tape or pipe thread compound since both types are threaded pipes. PEX connections are typically made with compression fittings, crimped on to create a water tight seal.

A wide variety of fittings are used in plumbing. Examples: brass, copper, CPVC, flexible, PVDF, cast iron, black, ABS, nylon, PVC and galvanized steel.

There are no normal connectors and thread types in plumbing. Plumbing threads come in different sizes and different styles. Common supply lines, for instance, generally have a 1/2-inch pipe thread on the end which attaches to the faucet, and one of three sizes on the end which attaches to the valve - 3/8-inch compression, 1/2-inch compression, or 1/2-inch FIP.

Types of connectors inlcude:

- OD Copper Tube

- Compression

7/8" Ballcock Toilet Connector

Also called: 7/8 in. Ballcock Nut. Screws on to bottom of toilet tank. Slightly smaller than standard 1/2" pipe thread. Typically on a braid water connector that is 3/8" compression on the opposite end. A Toilet Ballcock Assembly is the entire upright part inside the toilet tank with with valve plunger on top and screw connector that sticks out though the hole in the bottom of the tank.

Common fittings:

- 3/8 Compression X 7/8 Ballcock 9"

- Plastic Toilet Swivel Adapter, 1/2" PEX x 7/8" BallCock

This ballcock connector is part of a Flexible Water Connector, a braided hose that connects a faucet or toilet the the water supply stop valve. Toilet connectors are often either a Flexible Water Connector or a Flex Riser.

This illustration is a Braided Stainless Steel Toilet Tank Connector (Flexible Water Connector,) 3/8" Compression by 7/8" NUT x 12″ length.

Compression to Compression Straight Stop Valve

This compression shutoff valve has compression fittings on both ends, of different sizes. The inlet connection is 1/2" compression for pipes with 5/8" O.D. and the outlet connection is 3/8" OD compression. This is designed to be used with braided stainless steel connectors or risers. So the full connection path would be from the fixture, to the stainless steel connector, to this shutoff valve, then to the 1/2" water supply copper pipe.

1/2" Pipe Thread

Also called: 1/2" NTP. National Pipe Thread Tapered Thread. This type of pipe thread is tapered so that the fit tightens as the pipe is twisted in. Common residential NTP pipe use is for water and natural gas.

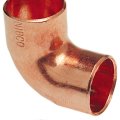

3/4" Wrot Copper

Wrot copper solder pressure 90-degree elbow is used with residential copper pipe installations for water, air conditioning and refrigeration.

1/2" PEX Faucet Connector

This connector allows a 1/2" PEX water line to go directly to a bathroom sink connector. It is a 3 piece connector consisting of the plastic outer threaded part, a rubber seal ring, and a copper internal nipple that receives the 1/2" PEX water line, sealed by a crimp ring (crimp ring not included.) The 3 piece connector is sold as a single unit. Do not use (PTFE) tape or pipe thread compound as this unit seals by compressing the rubber O ring to the fixture connector. Note the absence of a shutoff stop valve. If a PEX manifold is used, and the fixture has dedicated lines, the water can be shutoff at the manifold without shutting off the water to other household fixtures. A plumber may still choose to install an optional local stop valve even though it is not necessary.

1/2" PEX to 3/8" Compression

A very common connector used in installations where a home is being converted to PEX. This connector allows 1/2" PEX to connect to compression fittings on fixtures, such as a kitchen sink, with the common 3/8" OD size. This is a straight style stop valve. Remember, OD is an "Outer Diameter" measurement, which is why it appears larger than the 1/2" PEX side of the fitting. Most kitchen sink faucets now have Flexible Water Connectors built in with 3/8" OD fittings. However, there is a lot of diversity in fixture connections and you can never count on something being "common." This stop valve is a "quarter turn" valve, which lasts longer than the older style shutoffs which had an internal compression washer that would go bad.

Transition Coupling PEX to CPVC

This coupling allows for PEX line to be connected to existing CPVC plastic water line. Some hybrid residential water systems have CPVC, galvanized, and copper at different places in the plumbing, due to various upgrades, repairs, and remodeling over the life of the home. This is especially common in older homes. When removing old galvanized pipe, a plumber may choose to leave some places that have been converted to CPVC in place. This 1/2" PEX to CPVC coupling allows PEX to be connected to existing CPVC pipe. The illustration below shows the inside of the coupling, which is plastic. While the outside is copper, the plastic inside is meant to accept insertion of the plastic 1/2" CPVC pipe. Use PVC primer (purple in color) and CPVC cement to seal the pipe to the coupling.

Because the purple primer will soften the pipe surface, it is important to apply solvent cement to the pipe and fittings while the primer is still wet to achieve maximum bond strength. Coat the plastic inside of the coupling as well as the CPVC pipe you are connecting it to with the purple primer before applying the adhesive cement (CPVC pipe glue).

Quick Connect 1/2" CTS Coupler

Quick-Connect connectors are becoming increasingly more popular in pluming installations with hybrid pipe types. Pictured is a 1/2" CTS to 1/2" CTS quick connect coupler. CTS stands for Copper Tube Size. With this connector you can join connections to PEX (plastic) CPVC, and copper tubing. They seem to be reliable and are certainly very easy to install. Inside the connecter are rubber seals, plastic and sometimes metal pieces. Like a Chinese finger trap, you can insert the pipe in and it locks from coming back out. It is possible to unlock to remove the pipe if necessary. The CPVC, PEX, or copper pipe is inserted all the way, and a water tight seal is created. Water pressure just aids in the locking action and seal. When used with copper, ensure that the copper is clean and smooth, with no corrosion. If pressed onto copper with corrosion present, there will likely be leakage. It is recommended that you cut the copper tubing, clean it, and mark it just as you would with preparing for any other method of fitting connection. However instead of having to solder, you can simply push the fitting onto the copper until it reaches your mark and snaps tight. Finally, pipes connected with quick connect couplings can be rotated without causing a leak. Also, since there is no opening reduction there is no loss of water pressure or flow.

Garden Hose Thread (GHT)

The threaded connector type used for garden hose connections is called a Garden Hose Thread (GHT) connector. Specifically, the standard size is typically referred to as 3/4-11.5 GHT, which means it has a 3/4-inch diameter with 11.5 threads per inch.

Pipe Thread Types

- Pipe Threads

- Compression Threads

- Flare Fittings

American Tapered Pipe Threads NTP

Two of the more popular thread forms used are the Dryseal American Standard Taper Pipe Thread (NPTF) and American Standard Straight Pipe Thread for Mechanical Joints (NPSM). Pipe thread sizes are described much as bolt sizes are. Pipe threads must make a mechanical joint and leakproof connection. To accomplish this, the threads become shallower the farther they are from the end of the pipe. The bottoms of the threads aren't on a cylinder, but a cone. The cone taper is 1/16" in 1", which is the same as 3/4" inch in 1'. American Standard Taper Pipe Threads (NPT) is defined by ANSI/ASME standard B1.20.1.

MIP stands for Male Iron Pipe, also known as MPT Male Pipe Thread. It is a term for pipe fittings. FIP stands for Female Iron Pipe, also known as FPT Female Pipe Thread, and is a term for pipe fittings that MIP fittings go into. The difference between FIP, MIP and Compression fittings is in the tapering of the thread.

- Common Terminology: MIP (male pipe thread), FIP (female pipe thread) or NPT (national pipe thread)

Teflon tape or thread sealant compound is used on the pipe threads to help create a proper seal.

Some examples of pipe materials making use of MIP fittings include: galvanized steel, black iron, PVC, and sometimes thick copper. Galvanized steel most commonly for water, black iron most commonly for natural gas.

Compression

Compression threads are not tapered. Because compression threads are measured by the size of the pipe, they are smaller than NTP. Note that a 1/2" compression thread is significantly smaller than a 1/2" pipe thread. Compression thread is common with copper tubing. A metal or plastic ferrul is used (which looks like a ring slipped over the pipe, that the connection compresses down on to create a water tight seal.

- Sink faucet supply lines often use compression threads.

- A 1/2" copper pipe has a 5/8" OD measurement.

Flare

Flare fittings are somewhat rare in residential plumbing. There are some examples of their use. A special flaring tool has to be used to create the flare end on the copper tubing. This then seats inside the flare fitting to create a water tight seal.

Galvanized Steel Pipe

Galvanized pipe is steel pipe covered with a protective coating of zinc which greatly reduces its tendency to corrode and extends its life expectancy. Public water supplies treat their water to make it essentially non-corrosive. However, plumbers will tell you that when they remove galvanized pipe, it is typically internally full of corrosion. Galvanized pipe is no longer commonly installed in residential water systems. Galvanized pipe was used extensively as water supply lines in new construction prior to the 1960's.

Calcium buildup and oxidation occur internally, causing a loss of water pressure as the opening inside the pipe decreases. A moderate level of calcium helps form a protective coating on the pipe, which may slow down corrosive effects. Even so, the pipe still corrodes over time, and fills with rust. Over time, the pipes might corrode to the point where the pipes are completely restricted due to rust. If the water system has been shut off for a period of time, such as between home owners, this can accelerate the level of corrosion internally, causing the pipe to rust from the inside out, and even leak when pressure is reintroduced.

Galvanized steel can last roughly forty years until it needs to be replaced. Hard water in the home generally reduces the life expectancy of galvanized pipe.

Copper Pipe

Copper Water Pipe Fittings

Copper water pipes are durable, easy and flexible to install, and resistant to weather and bacteria. They resist bacteria because copper is biostatic. Copper pipe comes as tempered lengths that are hard, and annealed, or malleable coils known as soft copper. Unlike CPVC, or chlorinated polyvinyl chloride tubing, copper plumbing doesn't release toxic gases in the event of a fire because it resists burning.

The use of copper has somewhat decreased in residential installations due largely to the dramatic increases in price. Copper as a metal has become excessively valuable. Also, the popularity of and ease of PEX Supply Water Piping has impacted the popularity of both copper and CPVC.

- Cast: Cast copper fittings can be used in drain, waste and vent systems.

- Wrot: Wrot copper fittings can be used in a variety of water related applications.

- Press: Press copper fittings provide secure, reliable joints. A specially engineered O-ring and press-fit tool work together to create a watertight seal.

- Related: Pre-soldered fittings are Wrot fittings with the solder inside at the joint which can be heated to create a bond. Plastic Push fittings, also known as Push and Go, can be used to connect two copper pipes, as well as pipes of different materials. Push and go work on joining copper, PEX, CPVC, and polybutylene pipes.

PVC Plastic

These are three different types of plastic pipe used in plumbing applications. PVC is Poly(Vinyl) Chloride, CPVC is Chlorinated Poly(Vinyl) Chloride and ABS is Acrylonitrile-Butadiene-Styrene. PVC and ABS pipe are normally used for drain, waste and vent (DWV) systems, while CPVC is used for water distribution systems.

CPVC Water Supply Line

CPVC (Chlorinated Polyvinyl Chloride) is a chlorinated form of PVC that is accepted by building code in most areas for the installation of water supply lines.