Arc Lights also known as HID Lights

An arc light is a High Intensity Discharge (HID) light that uses a voltaic arc between two electrodes in a gas-filled tube which causes a metallic vapor to produce radiant energy. The electrodes are in close proximity within a sealed gas filled tub and is under pressure. The arc generates extremely high temperatures, causing metallic elements within the gas atmosphere to vaporize and release large amounts of visible radiant energy.

The HID light bulb does not receive direct line voltage like a filament lamp. A ballast is used much the same as with fluorescent lighting. The ballast is specifically designed for the type of arc light bulb being used. HID lamps require a warm-up period to achieve full light output and any interruption disrupts the arc causing another delay to achieve full luminosity.

The first arc light was the carbon type. They existed in the 19th century and underwent various forms of improvement before being abandoned. The first arc lamp to be used in large numbers was known as the Jablochkoff Candle, developed in 1876 by a Russian telegraph engineer. The use of the arc light peeked around the year 1910.

Problems with the lights included hot sparks which often burned people and started fires. From a partial glass fixture to later development leading to the enclosed carbon arc light which limited oxygen exposure to the electrodes and improved longevity this type of arc light was eventually abandoned in favor of a sealed mercury vapor arc light.

The modern fluorescent light is a type of low pressure mercury arc light. The fluorescent tube is filled with mercury vapor gas. When the lamp is turned on, electrical currents excite the mercury vapor, causing it to emit ultraviolet light which is then filtered using a phosphor coating to reduce rays to visible light. The fluorescent bulb is a hybrid utilizing the principle of the arc light, however, is different in design as well as application.

Mercury Vapor

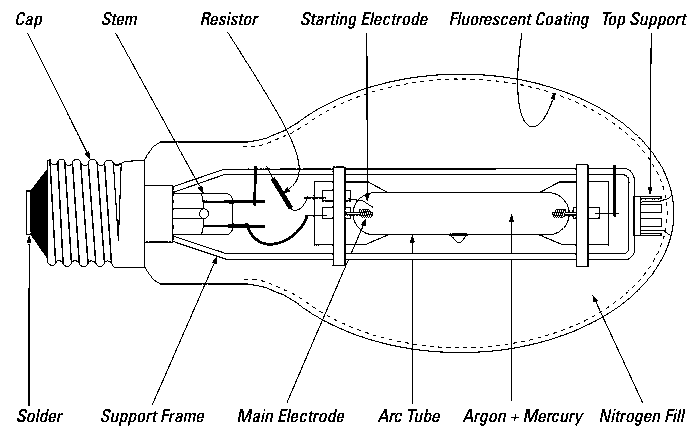

Mercury vapor lamps were the first high intensity discharge lamps to be commercially available for a wide variety of lighting applications. They use an electric arc through vaporized mercury to produce light. The advantages of Mercury vapor lighting is that it's more energy efficient than incandescent and most fluorescent lights, especially for outdoor applications

The mercury arc produces a bluish light that renders some colors poorly. Therefore, most mercury vapor lamps have a phosphor coating that alters the color temperature and improves color rendering to some extent. Most street lights once used Mercury vapor bulbs but have since been replaced by low pressure sodium lighting. Mercury vapor lamps provide about 50 lumens per watt, but ballast loss can reduce the system efficacy to about 30 lumens per watt.

There are still a lot of mercury vapor lights in rural America. The are common in the Midwest for the lighting and security on farms. Light service is often provided by the local electric utility company. Mercury vapor lighting is becoming obsoleted by metal halide and ceramic metal halide lights. New environmental restrictions ban the manufacturer and import of components of the mercury vapor fixture including the ballast. Replacement bulbs remain legal to produce and sell so that existing fixtures may remain in use.

Metal Halide

The metal halide light is a more advanced version of the older mercury vapor type. Metal Halide bulbs use chemical compounds known as "halides" that produce light in most regions of the spectrum. The bulb offers both energy efficiency with excellent color rendition. Metal halide lamps are similar in construction and appearance to mercury vapor lamps. The addition of metal halide gases to mercury gas within the lamp results in higher light output, more lumens per watt.

Metal halide lamps have an average life of 15,000-20,000+ hours. They produce 65-115 lumens per watt, more than fluorescent or mercury vapor lamps. The color temperature range is 2700K to 20,000K and CRI (color rendering index) of 65-90. Metal halide generates light closer to sunlight than any other HID light source.

Metal halide is frequently used in indoor settings such as factory lighting, gyms, and other large indoor lighting for large spacious areas. They should not be used for small enclosed areas. Metal halide lights are also used for outdoor security lighting such as parking areas.

Low Pressure Sodium

This bulb type is even more energy efficient and survives longer than the high pressure sodium light, however, color rendition is further sacrificed to a deeper orange colored light. Both types produce an orange tinted light, yet the LPS arc light is much more orange and everything it illuminates also appears orange in color.

Next to LED lighting, the low pressure sodium arc light is the most efficient light in the world because nearly 100% of the light produced is within the visible spectrum and not wasted as UV or infrared heat. The LPS light produces 100-190 lumens per watt and the typical bulb lasts around 18,000 hours.

Most street lighting uses low pressure sodium bulbs. However, with the introduction of new LED technology, as LED bulbs are now becoming bright enough many towns and cities across America are switching from low pressure sodium to LED street lights.

High Pressure Sodium

This bulb is designed with a greater focus on energy efficiency rather than color rendition. Mercury and sodium vapors in the ceramic arc tube produce an bright orange tinted light with extremely high LPW performance and longer service life. This type or arc light has better color rendition than LPS yet is still not nearly as good as metal halide.

High pressure sodium lights are widely used in industrial areas for nighttime outdoor security lighting. These lights are typically in a fixture known as a wall pack or on a pole. They are also commonly used for street lighting in North America.